Construction Cones: A Modern Invention of the U.S.A.

Construction cones are a regular fixture in the United States. We see these modern inventions keep construction workers safe on the site, redirect traffic on our National Highways, and even warn patrons of hazards in our retail stores.

The new traffic cone is the result of years of testing, experimenting, and engineering improvements. Even though construction cones are used in thousands of cities across the United States, we often overlook them in our daily lives.

Modern traffic safety cones are the result of careful testing and extensive engineering improvements. No matter how safety traffic cones are used, they are the preferred method to help identify hazards in the lives of millions of Americans.

The History Of Construction Cones

Originally developed by Charles D. Scanlon in 1940, traffic safety markers have their origin in identifying hazards for pedestrians and automobile drivers alike.

Mr. Scanlon first got the idea for the original road safety cone while he was working with the Los Angeles Street Painting Department to help divert pedestrians from stepping in the wet paint as the crews work in the city.

The first traffic safety markers were made from thick wood planks that were hard to handle and breakable.

The common version of the traffic cone in the 1940’s was a small, wooden tripod shaped design that had to be assembled on site and was often run over by automobiles. Learn more about the history of traffic cones.

New Materials For Increased Versatility & Durability

Not long after the first Safety Markers were built, Mr. Scanlon begins sewing strips of used tire skins together to make a more permanent traffic safety marker.

A few years later during 1941 - 1943, the manufacturing of cone-shaped road markers was designed from more resilient materials so they would not break or cause damage when struck by a vehicle.

After years of safety testing and improvements in manufacturing, The City of Los Angeles started using the traffic cones produced by Mr. Scanlon in 1947.

City officials favored the durable and non-destructive materials of the traffic cones over the iron handles the city used at the time to help delineate additional lanes of traffic during periods of high traffic congestion.

Orange & Lime ConesInternational Growth And Popularity

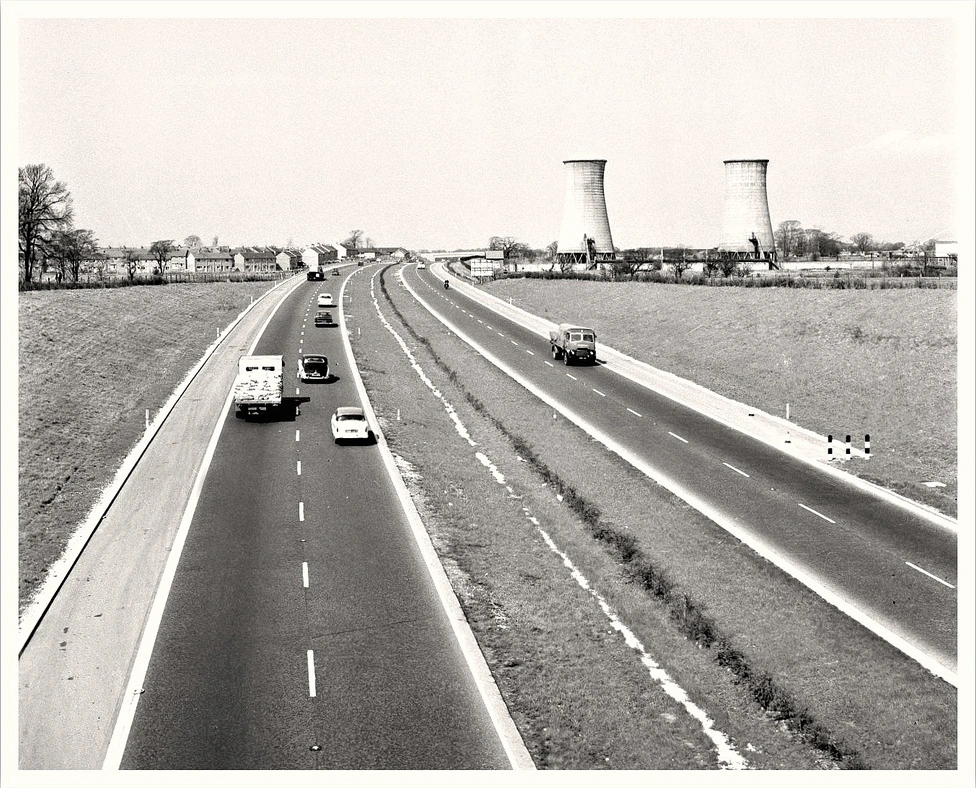

The first large-scale use of traffic cones to help direct traffic at high speeds outside of the United States was in the United Kingdom.

In 1958, the U.K. needed a better alternative for red lantern paraffin burners there were being used during the construction of the Preston Bypass.

City officials throughout the United Kingdom praised the versatility and durability of the traffic cones over the street lamps used at construction sites across the country. Instead of relying on lamps that easily tipped over and required fuel, the traffic cones provided visibility and redirected traffic without risking damage to automobiles.

Grabber Cones

The Federal Highway Administration’s Standard

In 1961, the Federal Highway Administration required that all vehicles cones be painted yellow or yellow-orange and have red trim at the top for increased visibility. By 1966, this design was not suitable for the substantial increase of drivers on the road throughout the United States. As a result of a dramatic rise in accidents and fatalities, the Federal Government passed The Highway Safety Act.

As a consequence of the Highway Safety Act, mandates for traffic cones and safety tools were created called the Manual on Uniform Traffic Control Devices (MUTCD). In 1971, MUTCD established requirements for traffic cones, resulting in the new traffic cones

Today there are millions of traffic cones used throughout the world. Cones are used on rooftops, sports fields, and parking lots for all kinds of projects and applications. What started from a small shop in Los Angeles to redirect pedestrians from stepping in wet paint has grown into a worldwide product that improves the safety and efficiency of our public roads and workspaces.

View All ConesThe Many Ways That Construction Cones Are Used

While initially made to guide traffic safely, the use of construction cones has moved into many other areas. No matter how construction cones are used, their purpose remains focused on identifying obstacles and signify caution. A few of the most recent methods of construction cones include:

- Sports training facilities

- Drivers education and job training

- Animal training courses like dog competitions

- Parking lot maintenance

- Staging areas in construction zones

- Property hazards used after an accident or bad weather

- Indoor caution areas, usually seen in warehouses and other industrial areas

The uses of construction cones have expanded well beyond their original use, and the need for traffic cones has grown more than anyone could have imagined.

SlimLine Traffic Cones

Code Requirements For Traffic Management

When construction cones are used for traffic management, the U.S. Federal Highway Administration requires cones to be fitted with white reflective bands to increase night time visibility.

These bands are made from reflective plastic and can be permanently attached to the cone or have the option to slip on and off the cone for specific applications.

The main benefit of traffic cones is that they are designed for high visibility and easily movable. These cones come in a variety of shapes, sizes, and colors.

Shop 28" ConesConstruction Cone Requirements For Traffic Management

The primary use for construction cones is to help divert traffic. These cones are typically painted fluorescent “safety” orange because it is the easiest color to distinguish from the color of the sky. They also tend to have reflective striping on them to increase visibility during the night.

The most common sizes of traffic cones used in the United States include:

- General indoor and outdoor projects should use 12 inches tall and weigh 1.5 lbs

- Outdoor applications like highway painting projects should use cones that are 18 inches tall and weigh 3 pounds

- Metro cones are often employed in cities for local street projects and should be 28 inches tall and weigh 7 lbs

- Cones used on highways with speeds over 45 MPH; cones must be 28 inches tall and weigh 10 pounds with reflective stripes

- General highway projects must use traffic cones that are 36 inches tall and weigh 10 lbs with reflective strips

Indoor Uses For Construction Cones

Cones are not restricted to only outdoor use, and many indoor public spaces use safety cones to mark off areas or hazards or identify locations that are closed to pedestrians. Safety cones are commonly employed in stores to determine slippery floors, or when a restroom is closed for cleaning.

Many schools use traffic safety cones in pick up and drop off areas, to ensure the proper flow of traffic and reduce overall congestion. They are also used on basketball courts and soccer fields for practices and training purposes.

Since safety cones are distinctive, portable, and easy to handle, they are the perfect solution to a wide range of problems and situations. It is no wonder why construction cones have become a staple in our daily lives, and their presence is seen almost everywhere around us.

Colored ConesWhat To Look For In A Quality Traffic Cone

Not all traffic cones are created equal. If your project demands the highest durability for extended use, then the experts at Traffic Safety Story have you covered. We have worked with business leaders in a wide range of industries.

As a trusted leader in traffic safety supplies, we work to ensure your construction cones are delivered on-time and meet your needs. Our road safety consultants are available to answer your questions and help you choose the right construction cone for your needs. Among the most important aspects to double-check on before purchasing traffic cones includes:

- High-visibility PVC design, using current injection molded cone production process

- The fluorescent orange color used throughout the body of the cone. The material should be treated to resist fading and provide continued high visibility protection.

- Construction cones should be constructed from a single-piece mold and not have a vertical seam along the face of the cone.

- The cone should be permanently molded to a dark black based for stability and longevity. This prevents separation upon impact with another object and increases grip on the road.

- Traffic cones should be stackable for storage and resist sticking when removed from each other.

- Cones must meet MUTCD Standards (http://mutcd.fhwa.dot.gov/) when used on public roads or other applicable public locations.

With so many industrial and commercial applications for construction cones, it can be difficult to understand the type of safety cone you need for your project. The Traffic Safety Store has years of experience helping customers just like you choose the perfect safety cone marker for any project or application.

YGive our trusted experts a call when you are ready to find the traffic safety supplies you need. Our team will work with you to find the best solutions to your problem, and our commitment to speedy delivery will have your traffic safety products delivered to you in no time. Contact us today to learn more!(contact@trafficsafetystore.com)

Need Help? Please contact us

contact@trafficsafetystore.com or call 800-429-9030